Cycle

After gold bearing ore has been mined, it is hauled from the open pits and underground mines to the ROM (run of mine) pad and separated into stockpiles to begin the six-stage processing cycle at our Processing Plant.

Crushing & Grinding

Ore from the stockpiles is fed into the primary crusher located next to the ROM pad. The jaws inside crush the rock down to fit through the 125mm gap at the bottom. Crushed rock then travels to the mill.

As the mill turns, steel balls inside are lifted up against the mill walls and fall onto the rock to crush and grind it even further. At the same time, water is pumped in to turn the crushed rock into a thick liquid called slurry.

The slurry is pumped into the primary cyclones (used to size the material). Coarser material falls to the bottom and returns to the crushing/grinding cycle while the lighter material spins up to the top and is pushed over onto the next stage.

Flotation & Oxidisation

The flotation unit cells are the first opportunity to separate the gold bearing ore from waste rock.

The main material mined at Macraes is sulfide ore (containing gold particles). SIBX (Sodium Isobutyl Xanthate) is pumped into the slurry and causes the gold particles to bond with the sulphur inside the rock. Air is used to agitate the slurry and float the gold bonded sulphur over the top of the tanks onto the next stage.

This process is repeated several times to concentrate the gold bearing ore and separate it from the waste rock (increasing the grade of the ore). The flash flotation units catch 70% of the gold collected at Macraes, with the primary roughers collecting the other 30%. The slurry that doesn’t contain any gold is neutralised and sent to the tailings dam. The concentrate is thickened and then fed into the autoclave to make the minerals containing the gold porous, replicating natural weathering just much much faster.

The autoclave is a 12-metre long, high pressure, high temperature vessel and one of a kind in the Southern Hemisphere. It allows us to release the gold from the refractory ore we have at Macraes.

The gold is liberated through the reaction between oxygen and sulphur under pressure. Once the reaction starts, fresh slurry is fed into the autoclave and oxidised slurry is discharged to the next stage of the cycle.

Leaching and Absorption

The oxidised slurry travels to the carbon leach circuit to dissolve the gold out of the rock. It moves through a series of gravity fed tanks containing small amounts of sodium cyanide, with higher concentrations at first and weaker at the end of the line. The sodium cyanide leaches the gold from the rocks turning it into a liquid. It can take three to four days for a particle of rock to travel through the tanks.

By the time the rock particle reaches the last tank, 98.5% of the gold is recovered. At the same time, activated carbon (coconut husks) are pumped upstream through the tank system to catch the leached liquid gold. Once full of gold, the carbon travels to a gold desorption column designed to wash the gold out of the carbon.

When this process is complete, all that is left is eluate containing hot water, gold solution, cyanide, and caustic soda. The eluate is transported to the gold room and electroplated onto cathodes wrapped in steel wool. The steel wool is then melted in a furnace, the liquid gold sinks to the bottom and the remaining waste and inpurities rise to the top and forms what is known as slag.

As the bar is poured the slag flows out first and is followed by the gold. This causes the slag to overflow out of the mould, leaving behind just the gold in the shape of a bar. A sample is taken from the liquid gold to send to the Perth Mint in Western Australia to determine the purity and quality. The gold bar is removed from the mould and cleaned before being weighed and officially numbered.

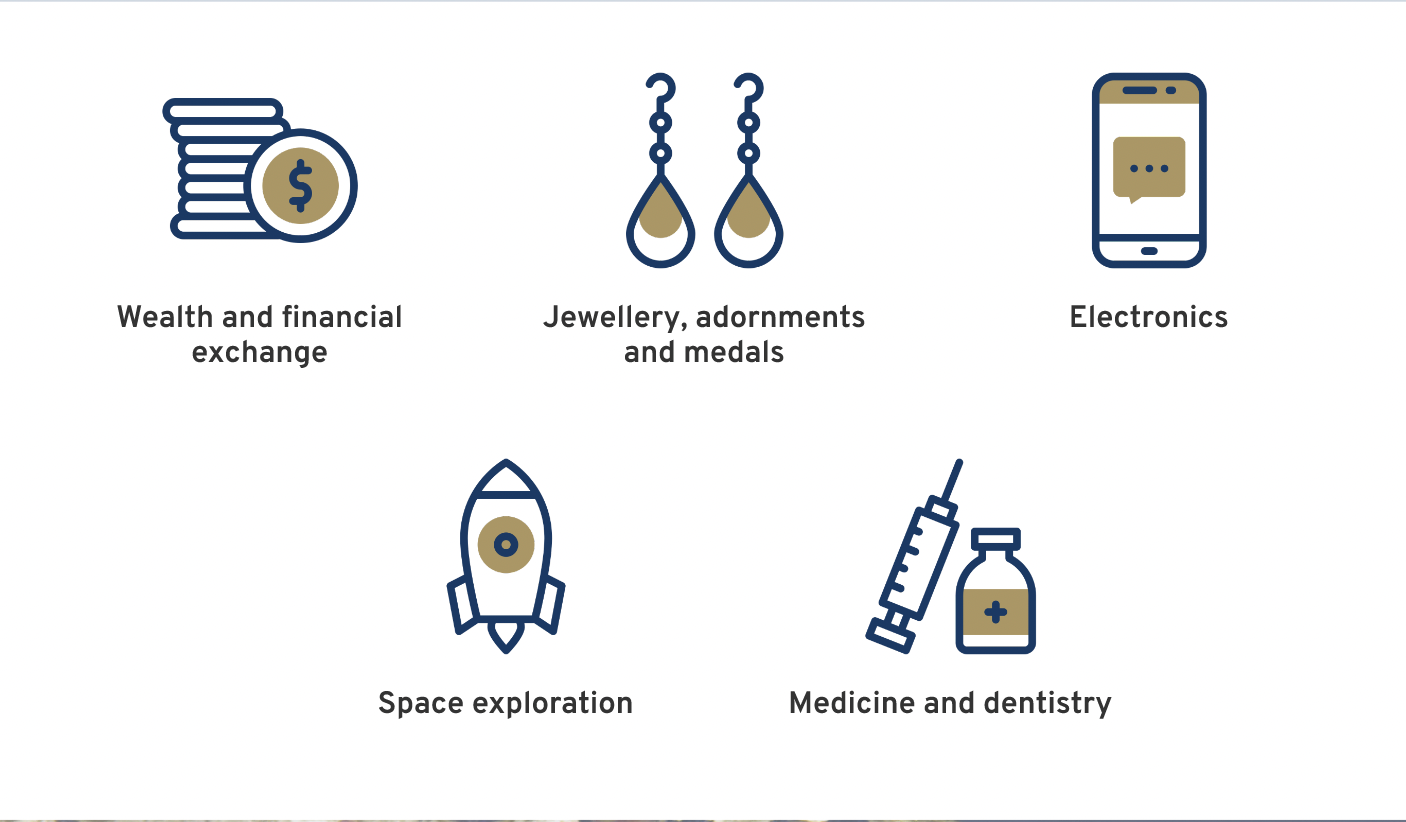

Where Our Gold Goes

Each gold bar poured at our operation is prepared to be shipped to the Perth Mint in Australia. Here it will be manufactured into a range of products, click here to see what our gold turns into.

Tailings

Tailings is the material that remains once the very small amounts of gold has been removed. This material is pumped from the processing plan to the crest of the earth embankment via a series of spigots. Before being pumped all traces of cyanide are destroyed, the material in the tailings dam is ground up rock with the gold removed.

Maintenance Shutdowns

Periodically parts of the processing plant wear out, these cannot be repaired safely whilst still being operated, routine maintenance shutdowns allow for the plant to be cleaned, maintained, and repaired.

Around 200-300 specialist contractors can be involved in a major scheduled shutdown.